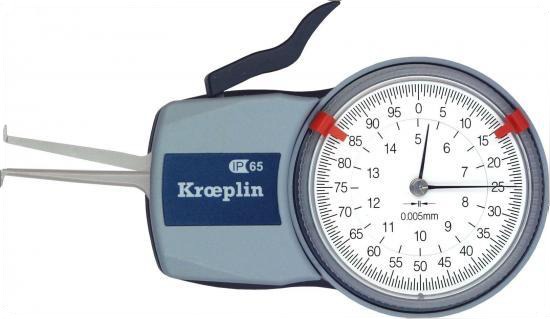

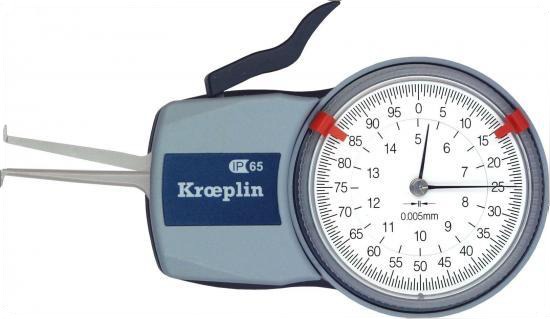

Groove diameter external gauge.

Measuring internal groove diameter.

It s not even necessary to take particular care aligning the groove gauge with the axis of the workpiece effectively de skilling the operation.

Allows measurement without distortion of the thin aluminum can.

Designed to measure the reform bead the round bottomed internal groove diameter on the underside of the aluminum can.

Length groove thickness and diameter mechanical internal measurement electronic internal measurement mechanical external measurement electronic external measurement foamed materials and foil thickness wall thickness measurement special applications request a brochure mechanical internal measurement kroeplin are the world s leading suppliers of precision calipers.

In the inspection area o rings measuring instrument is a special head produced by sangha metrology for measure the groove diameter of the bore.

The internal pitch diameter gage is ideally suited to check the internal pitch diameter of gears and splines.

Minimum measurement decimal inch 0 4000 maximum measurement decimal inch 1 2000 graduation decimal inch 0 0005 accuracy decimal inch 0 0015 contact point type ball ball material hardened steel groove depth decimal inch 0 1900 groove width decimal inch 0 0600 leg length decimal inch 3 3000 tip diameter mm 1 00.

Groove diameter internal.

The rok it groove gauge in engineering the difficulty of measuring the diameter of internal grooves is well known.

Precise groove measurement are made easily and accurately.

It is more suitable and accurate system which measure the groove diameter of the bore gauge.

Grainger carries a wide range of inside micrometers designed to help you obtain precise measurements of the inner diameter of nuts tubes and other objects.

The rok it groove gauge s spherical anvils make a quick positive readout a certainty.

Crest diameter mrp setting standards.

Available in a number of styles and configurations grainger can help you find the right micrometers that feature minimum and maximum diameters inside ideal for a range of applications.

Digital readouts dro linear scales.

Dial bore gages are used to quickly inspect hole diameter as well as to detect and measure all kinds of bore conditions such as taper bell mouth and out of roundness.

Three retracting blades positioned 120 degrees apart.

Granite plate accessories.